Modern society has rapidly become more globalized thanks to the proliferation of air transport. However, ocean vessels still play an integral role in connecting islands and continents by supporting the mass transport of passengers and goods. They comprise a wide range of applications, from freight vessels and passenger ships to drillships, navy vessels, fishing boats and more. NIDAK's cast products are used in essential parts and equipment for these vessels, such as sturn tube system sealing components, bearing sleeves for rudder stocks, and fin stabilizer devices.

Shipping parts that come in direct contact with seawater must not only exhibit a high level of resistance to corrosion, but also in many cases, display exceptional resistance to abrasion from sand and gravel when passing along rivers and other shallow water channels. Additionally, casting materials used in shipping parts on passenger vessels that traverse the ocean must deliver the highest level of quality in order to ensure the ship's safety and functionality.

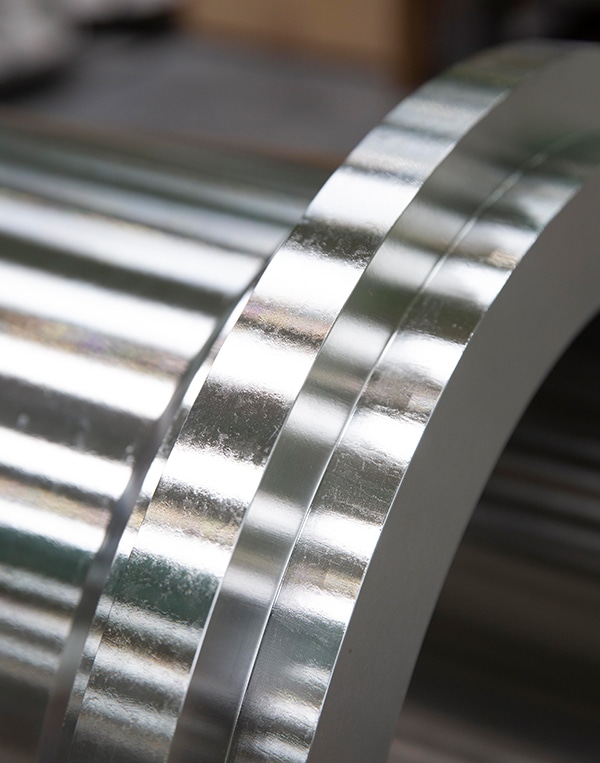

From freight vessels and passenger ships to drillships, navy vessels, fishing boats and more, NIDAK's products are used in a wide range of shipping applications. The quality behind NIDAK's centrifugal cast products is world class. In particular, our propulsion system/sealing components manufactured by vertical centrifugal casting processes have earned the long-standing trust of our customers over the years, allowing us to maintain top market share in our industry both domestically and abroad.

Just as ships come in a variety of sizes, so do the parts and equipment they use. NIDAK features a production system capable of handling small lot, multi-type operations, which allows us to flexibly meet our customer's varying demands for size and quantity. From one-time orders of small-lot items to the mass production of fixed quantities of contracted products, we are equipped with the agility to meet a full range of customer needs.

Shipping vessels traverse a diverse range of routes and expanses of sea. As such, the properties required of the materials being used vary greatly according to the intended application. At NIDAK, we conduct a variety of material tests based on the application information provided to us by our customers.

We provide our customers with results and opinions derived from investigations and research testing the rates of corrosion and abrasion under a specific set of conditions, and offer support in drafting designs and selecting materials. As your metal expert, we focus on delivering reliability and piece of mind at the best overall cost.